We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

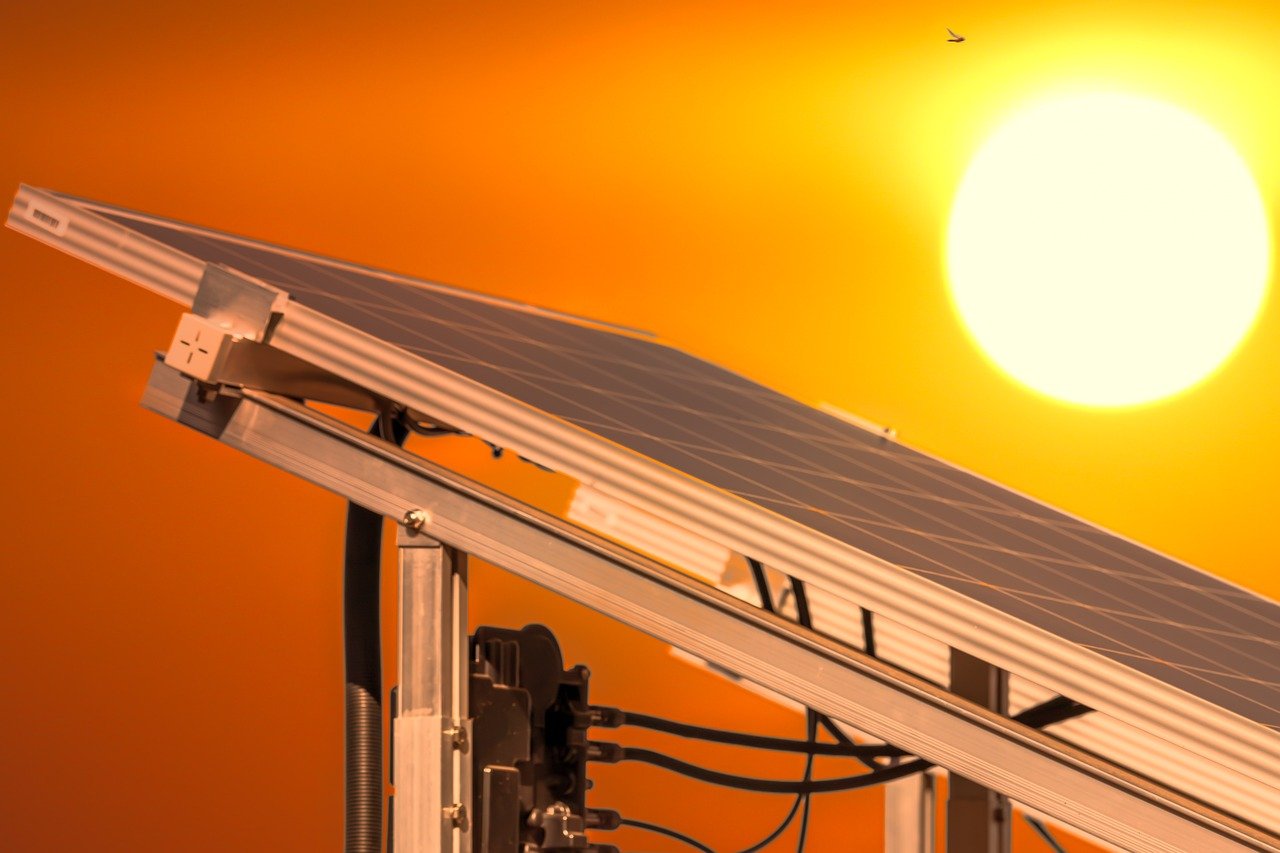

A technology to sustain requires adequate support from the government. While this was the case with solar energy before, the market dynamics has changed a lot now. With the evolvement of cost competent market, optimizing every component of the solar power plant is important to ensure developers sustainability and profitability. System voltage is one such area where optimization has been at steady pace. The initial solar plants were designed at 600V DC system voltage. However, oncethe drive of cost reduction had begun designers/developers started looking for more novel ideas to keep their profit margins balanced. One such idea was to increase system voltage to 1000V (from the previous 600V systems) citing its various benefits. A similar idea has been in rounds for quite a few time now i.e. to further increase system voltage to 1500V(Figure 1) from the existing 1000V. With modernization of various components, this shift may seem easy in few countries only. For country like India lot of shortcomings needs adequate thinking and appropriate action before such shift is made. This blog aims to explain its readers on both advantages and shortcomings of 1500V system. Additionally it would also inform its readers on the way ahead for Indian market for such system.

Figure 1 : A typical arrangement of solar modules in 1500V plant (Source: PVTECH)

Before delving into the shortcomings of a 1500V system, let us first understand their advantages. The advantages of using higher voltage DC system (1500V here) are as follows:

Figure 2 : A typical 1000V system (Source: Google images)

Resistance = Resistivity x Length of wire /Area of wire &

Power Loss due to heat = (Current)2 x (Resistance)

With such advantages, 1500V system sure looks like an attractive technological shift. However there are still few concerns which are to be addressed before we shift to such systems. They are as below:

Figure 3: Effect of PID on modules connected in a typical string Electroluminescence (EL) image (Source: Waaree Energies)

Additionally, while handling such high voltages,it is also important that appropriate safety equipment and/or Personal Protective Equipment (PPE) is used to curb the risk of safety hazard.

1500V systems currently areonly beneficial at utility scale power plant systems and not on rooftop scales. However it is poised that with increasing awareness and further reduction of cost in conjunction with availability of material, 1500V systems shall experience meteoric rise. 1500V system would see an increased market penetration of around 95% in the next decade. Thus it is important for India that an early adaptability and the necessary infrastructure up gradation are done in order to be prepared for the next technical shift.

Figure 4 : Projected adaptability of 1500V system (Source: ITRPV)

Waaree Energies had understood this market trend and have already launched 1500V compatible modules and inverter. They are tested rigorously in order to ensure they perform optimally when under operation.

Let us all pledge to make solar energy the primary source of energy in the near future.

RAHE ROSHAN HAMARA NATION

Notifications